Aquatec partnered with AT&L Consultants

for Goodman Property Services to investigate

servicing the second stage of an industrial

development with a pressure sewer scheme.

Specialists in complex Water and Wastewater projects

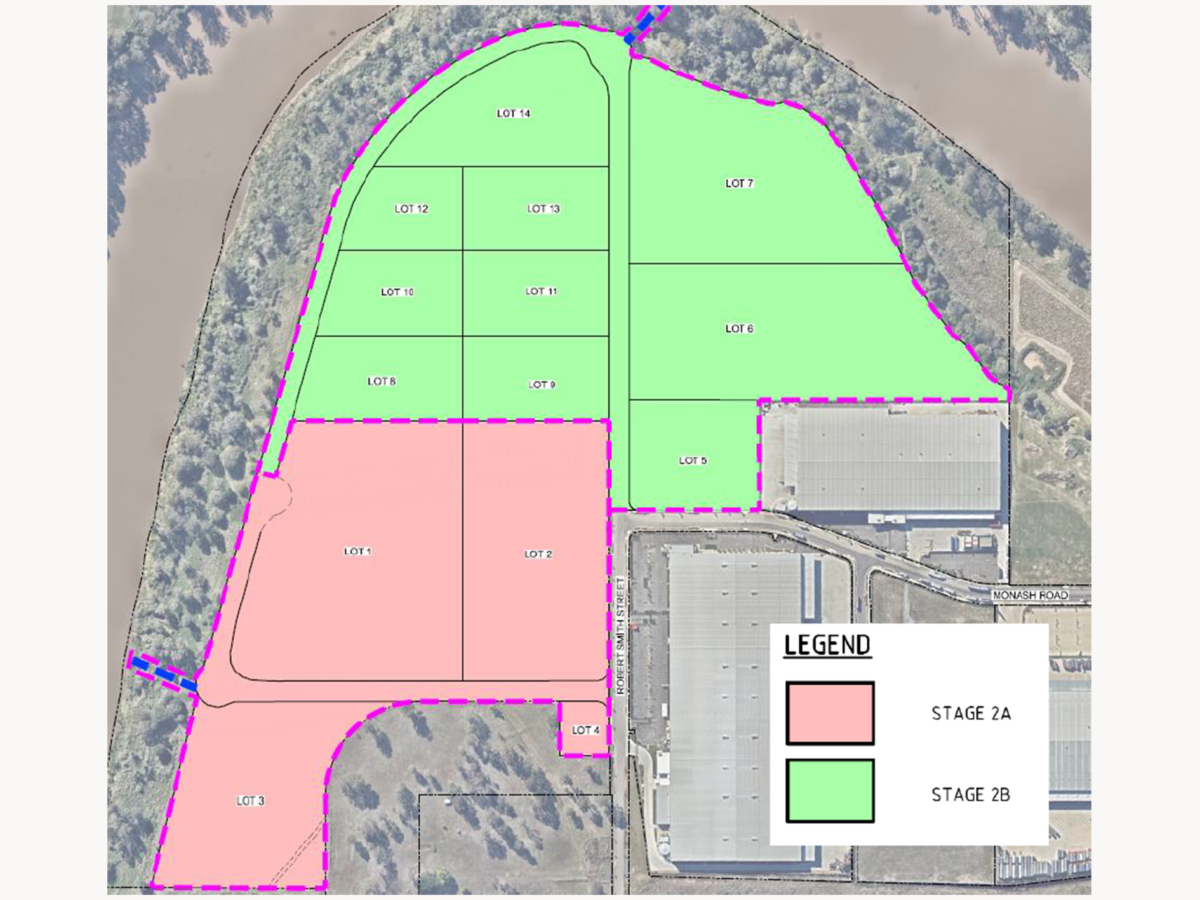

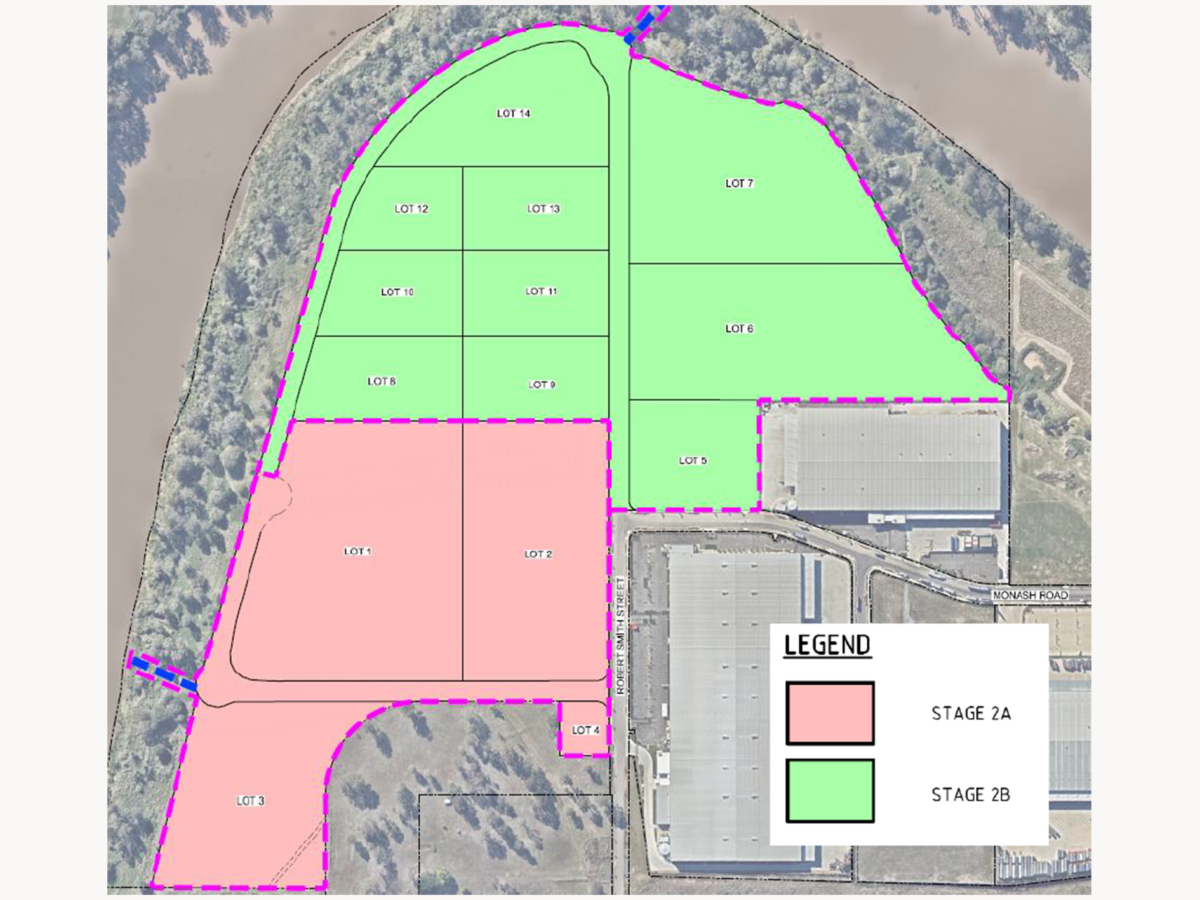

The Redbank Motorway Estate is a 60-hectare industrial development 20km from Brisbane, strategically located with direct access to the Ipswich Motorway. The business park is currently home to logistics giants TNT, DB Schenker and Northline, as well as a 50,000 square metre Australia Post distribution centre and the state-of-the-art Rheinmetall Defence facility for the manufacturing of armoured military vehicles.

The Estate has relatively few land parcels due to the large industrial tenancies, with Stage 2 consisting of 14 lots ranging in size from 0.3 – 5.9 hectares. There were several constraints on the sewer services design, including the site’s flat topography, dispersive soils, and the depth of the existing sewerage infrastructure at the downstream connection point.

“Aquatec were able to provide robust case studies which helped to convince the design team, the developer and QUU of the benefits of this option. Aquatec’s technical consultant attended several meetings and presentations with QUU in Brisbane in order to explain and gain acceptance of the solution.”

— Simon Haycock, Associate Director Civil Engineering, AT&L

Seeking an alternative solution

Before AT&L’s involvement with the project, a gravity sewerage solution was designed for the estate, culminating in a 10-metre deep pump station. Due to the potential presence of groundwater, cost estimates received to construct the gravity sewer exceeded budget allowances. Therefore, alternative options had to be considered.

Aquatec’s technical team developed a detailed design report to service Stages 2a & 2b with a centralised pressure sewer system and were able to see the project through to delivery.

“The communication from Aquatec’s personnel was very good and they were always very responsive to our requests. Aquatec has invested in working with industry-leading professionals to ensure their systems are as efficient as possible.”

— Simon Haycock, Associate Director Civil Engineering, AT&L

Innovative Control Systems Delivering Whole-Of-Life Network Benefits

- The cost of the pressure sewer network compared with a conventional gravity sewer solution was a key factor for this project due to a tight delivery budget. The use of pressure sewer with shallow, small diameter pipes presented a significant cost saving and eliminated the need to dedicate a portion of useable land for a public pump station.

- Aquatec’s user-friendly approach to design involved close collaboration with AT&L in order to understand the client’s needs and site-specific considerations. A number of revisions and enhancements were made as the project progressed to reflect changes in expected flows.

- Aquatec’s Infoworks ICM hydraulic model for the development of pressure sewer design ensures that the pipework size is optimised in accordance with WSA/SEQ guidelines. This in turn provides key advantages such as better self-cleansing velocities, reduced detention times, and reduced septicity and odour issues as a result.

- The ultimate tenancy type and land use for each lot were unknown during the estate design stage, so the pressure sewer design had to incorporate flexibility for on-lot pump units to be tailored to facility requirements during the construction phase.

- The operation of the Aquatec OGP+ pumps within the Redbank estate can be controlled using time-based operating parameters programmed into the OmniSmart controllers. This enables several pumps to be set to turn on simultaneously once a day, during the early stages of development. This process increases pipe velocities and generates a “flushing wave” through the reticulation pipework, negating the need for a manual flushing program.

End to end service with Aquatec

- Our team also provided commissioning, site support and staff training for each individual station, ensuring that the pump and control technology in use is identical for all installations across the site for consistency and ease of maintenance.

- Using the same control philosophy, the allotment pump systems can be regulated to switch off and utilise available on-site storage capacity during peak hours, and then operate during off-peak times when additional system capacity becomes available. These development control strategies were developed and tested in the model to create various control scenarios before being uploaded into the controllers on site.

- Aquatec is able to accommodate the unique requirements of each individual tenancy as the development expands. The Rheinmetall MILVEHCOE (MILitary VEHicle Centre Of Excellence – pictured below) facility is one example, which involved the amalgamation of three individual lots into one and required a high trade waste discharge volume to the sewer network.

- Aquatec customised the pressure sewer pump station design accordingly, engineering the fibreglass chambers to overcome challenging soil types and providing a large on-site storage vessel to balance wastewater flows.

- Overall, the pressure sewer design and installation exceeded all required specifications and received full support from Urban Utilities as the ideal servicing strategy for the project.